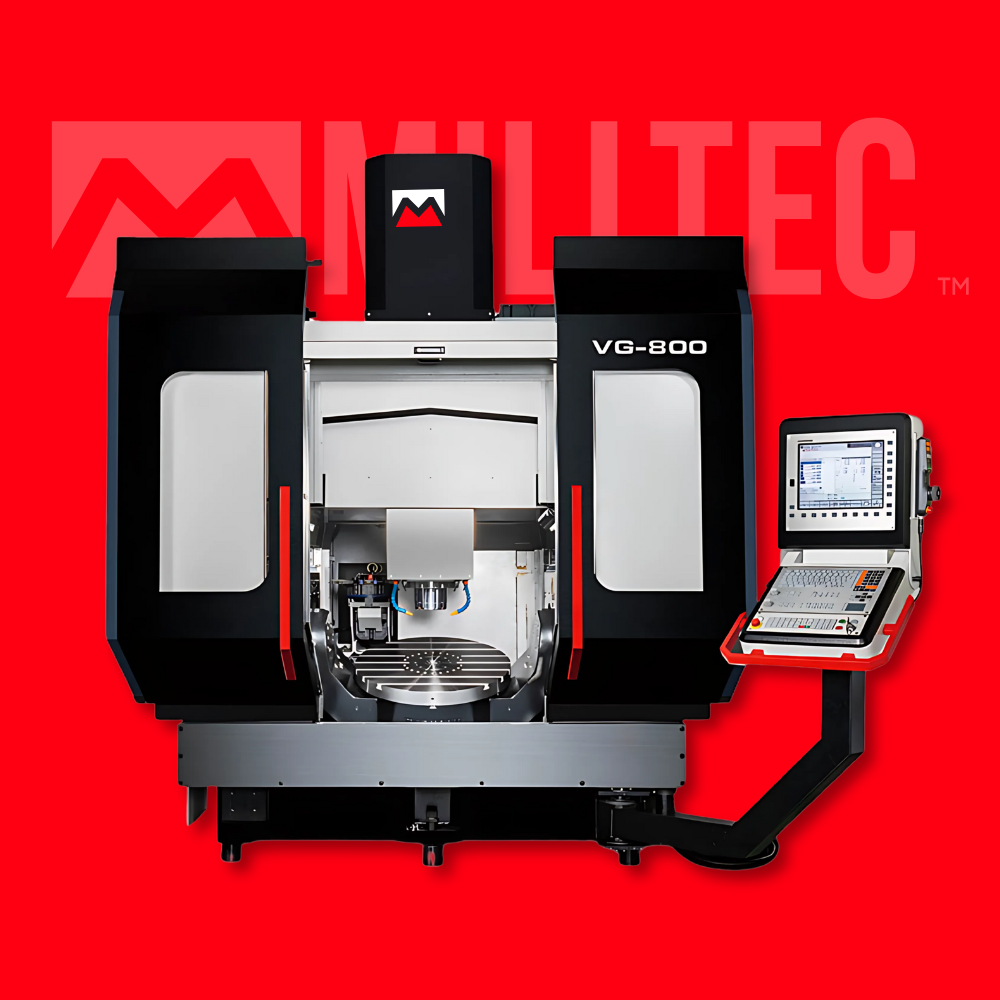

Explore the Milltec VG-800

Explore the VG-800

Product INFORMATION

The Milltec VG-800 Gantry-Type Machining Centre combines robust engineering with precision performance. Its rigid gantry structure and 800mm Z-axis travel deliver exceptional stability for heavy-duty machining operations, whilst the advanced high-speed spindle ensures superior surface finishes. Designed for demanding manufacturing environments across aerospace, automotive and heavy equipment sectors, the VG-800's generous working envelope and precise motion control make it the ideal solution for large-scale, high-accuracy component production.

Enquire Today

We will get back to you as soon as possible.

Please try again later.

Technical Data

| SPECIFICATION | |

|---|---|

| X TRAVEL | 800 mm |

| Y TRAVEL | 1,245 mm ( -510 ~ +390 +345 Tool change travel ) |

| Z TRAVEL | 620 mm |

| Spindle nose to table surface | 100 ~ 720 mm |

| Table Size | Ø 800 mm |

| T-slot (Q'ty x Size x Dist) | 7 x 14 x 100 mm |

| Max. Table Load | 1,000 kgs ( Horizontal ) / 500 kgs ( Tilting ) |

| ATC Capacity | 24 / 30 / 32 / 40 tools |

| CNC CONTROL | Heidenhain TNC640 / Siemens 840D |

| Spindle | |

|---|---|

| Spindle Transmission | Build-in |

| Spindle Taper | HSK-A63 |

| Spindle Speed | 12,000 rpm |

| Spindle Power (S1 100% / S6 60% / S6 40%) | 21 / 25 kW |

| ROTARY TABLE ( A/C Axis ) | |

|---|---|

| A AXIS TILTING RANGE | -120˚ ~ +30˚ |

| C AXIS ROTATING RANGE | 360˚ |

**Note: Specifications are subject to change without further notice.

Video demonstration

Video demonstration

Training & Support

We understand that continuous improvement is essential. Trust in our unparalleled training solutions and rest assured that you’re in capable hands when you choose Memtec.