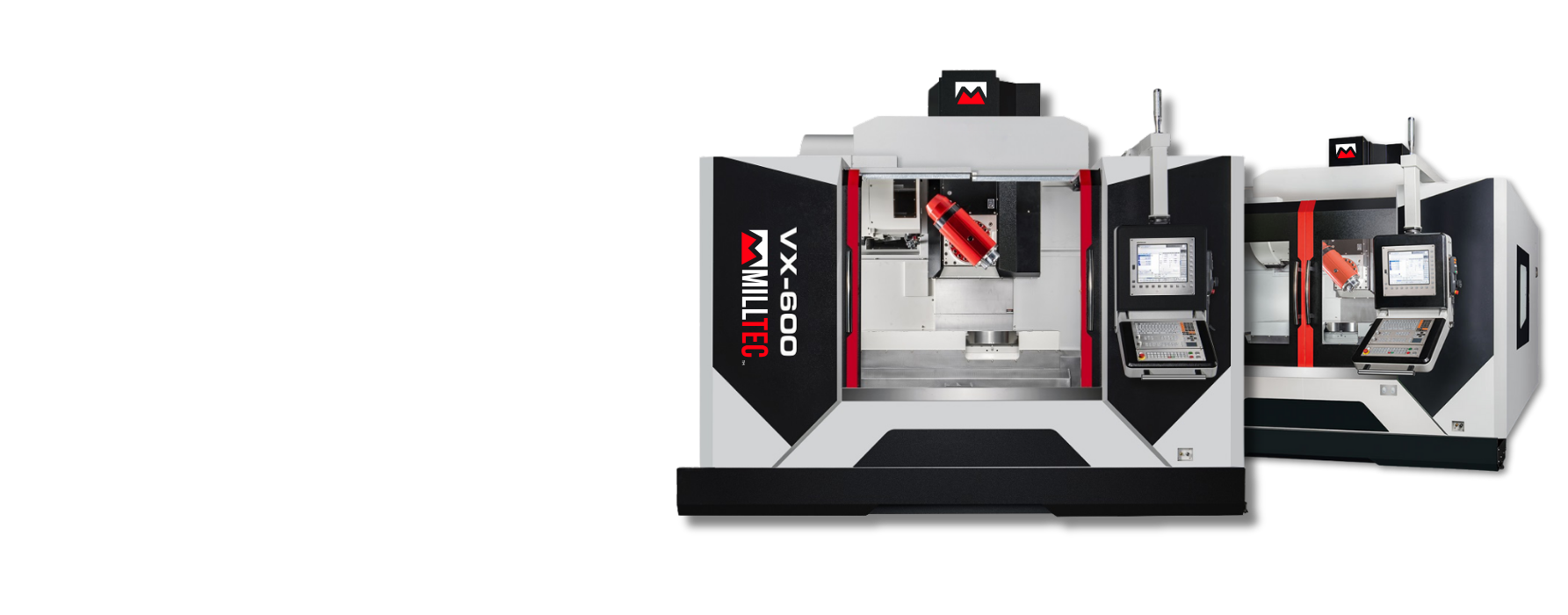

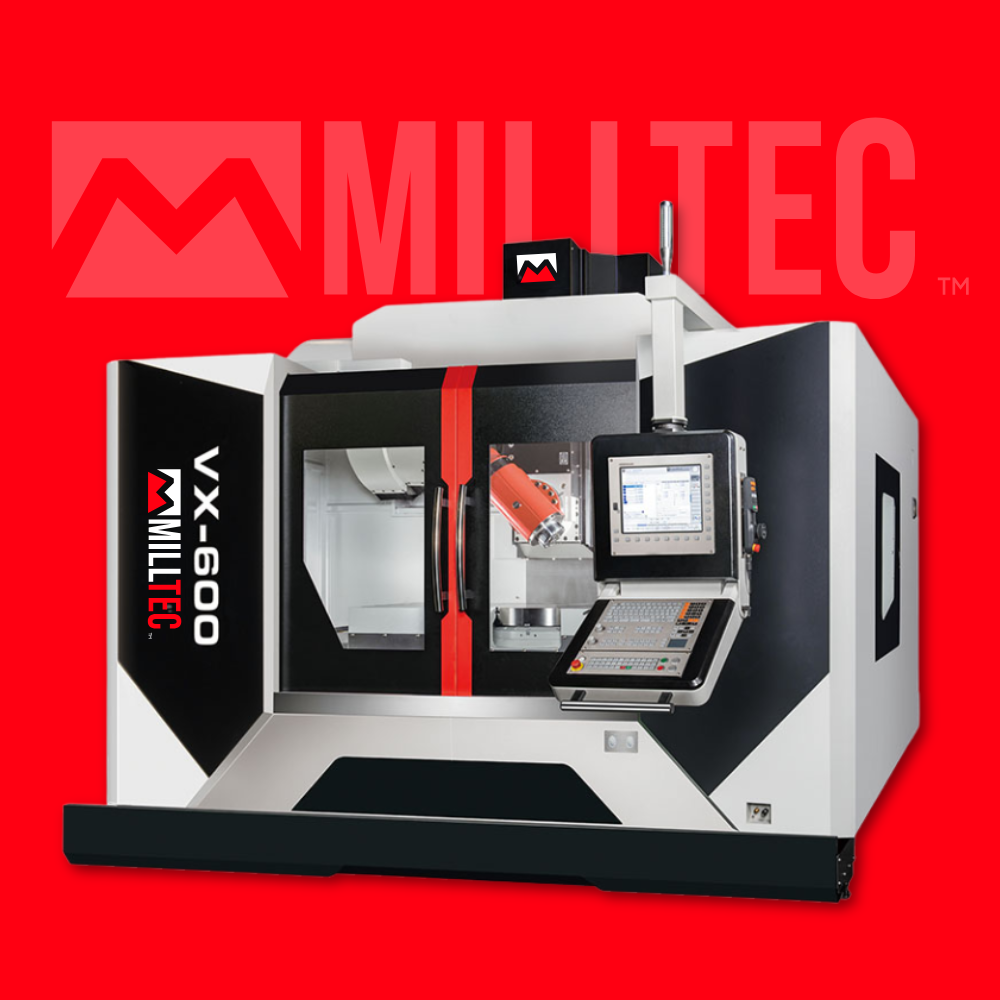

Explore the Milltec VX-600

Explore the VX-600

Product INFORMATION

The Milltec VX-600 5-Axis Machining Centre stands as a pinnacle of precision engineering excellence, purposefully designed for both small batch and high-volume production of complex components. At its heart, this revolutionary machine boasts a sophisticated 15,000rpm built-in spindle head with advanced swivelling capabilities, seamlessly paired with an embedded rotary table for true simultaneous 5-axis machining.

This powerful combination enables manufacturers across aerospace, automotive, and high-tech electronics sectors to achieve exceptional accuracy and superior surface finishes in a single setup, dramatically reducing production time whilst maintaining uncompromising precision. Whether you're crafting intricate aerospace components or precision automotive parts, the VX-600's robust construction and cutting-edge technology deliver outstanding high-speed performance that has earned widespread recognition for its reliability and precision across demanding industries.

Enquire Today

We will get back to you as soon as possible.

Please try again later.

Technical Data

| SPECIFICATION | |

|---|---|

| X TRAVEL | 1,300 mm |

| Y TRAVEL | 700 mm |

| Z TRAVEL | 700 mm |

| Spindle nose to table surface | 20 ~ 720 mm |

| Table Size | 700 x 1,450 mm |

| T-slot (Q'ty x Size x Dist) | 5 x 18 x 125 mm |

| Max. Table Load | 1000 kgs |

| ATC Capacity | 24 / 30 / 32 / 40 tools |

| CNC CONTROL | Heidenhain TNC640 / Siemens ONE |

| Tilting Spindle Head (B axis) | |

|---|---|

| Transmission | Worm gear |

| Tilting Angle | -110˚ ~ +30˚ |

| Spindle Transmission | Build-in |

| Spindle Taper | BBT40 |

| Spindle Speed | 15,000 rpm |

| Spindle Power (S1 100% / S6 60% / S6 40%) | 21 ~ 25 kW |

| ROTARY TABLE (C Axis) | |

|---|---|

| Transmission | DD motor |

| Table Diameter | Ø 630 mm |

| C Axis rotating Range | 360˚ |

| Max. Speed | 120 rpm |

**Note: Specifications are subject to change without further notice.

Video demonstration

Training & Support

We understand that continuous improvement is essential. Trust in our unparalleled training solutions and rest assured that you’re in capable hands when you choose Memtec.